Choosing the Right Automatic Bagger Machine for Your Packaging Needs

In today’s fast-paced manufacturing environment, efficiency, precision, and speed are key to staying competitive. For businesses looking to optimize their packaging processes, an automatic bagger machine can make all the difference. Whether you're packaging food, pharmaceuticals, consumer goods, or industrial products, choosing the right bagging machine is essential for ensuring smooth operations, minimizing waste, and boosting overall productivity.

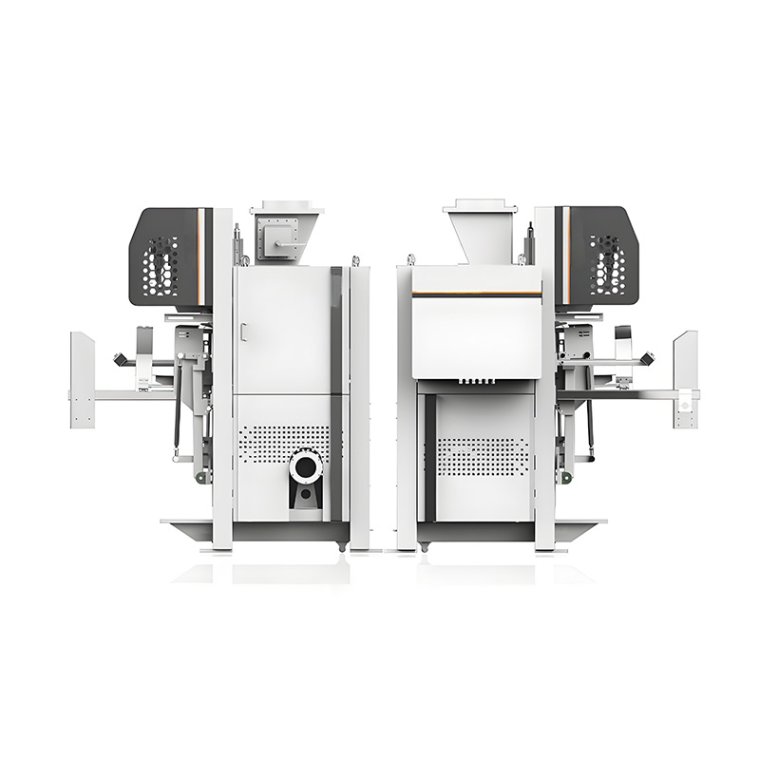

At Dostar Packing Equipment Co., Ltd., we specialize in providing innovative packaging solutions, offering both semi-automatic and fully automatic packaging systems. With years of expertise in the design, integration, manufacturing, and servicing of automated packaging lines, we are dedicated to helping businesses streamline their packaging processes and achieve greater efficiency. In this article, we’ll guide you through the key factors to consider when selecting the right automatic bagger machine for your packaging needs.

1. Understand Your Product Specifications

The first step in choosing the right automatic bagger machine is understanding the type of product you’re packaging. Different products require different bagging techniques. For instance, the bagging requirements for loose products like snacks or small components will vary significantly from those needed for bulky or fragile items.

Key considerations include:

-

Product Size and Shape: Are your products irregularly shaped, like bulk vegetables, or uniform, like tablets or powders? For irregularly shaped items, you may need a more versatile bagger machine capable of handling diverse shapes and sizes.

-

Weight: Some products are heavier, which could require stronger, more robust machinery that can handle the weight without causing damage to the product or the machine itself.

-

Fragility: If your products are delicate or easily damaged, you may require a bagger machine with gentle handling mechanisms to avoid crushing or altering the product’s appearance.

At Dostar Packing Equipment Co., Ltd., our machines are designed to handle a wide range of products, from food to industrial components, ensuring that each product is packed efficiently and securely.

2. Packaging Speed and Throughput

Another critical factor in selecting the right automatic bagger machine is the speed at which it can operate and the throughput it can handle. The packaging speed should match your production requirements to ensure optimal efficiency. A machine that is too slow can create bottlenecks in your production line, while one that is too fast may lead to waste, errors, or inefficient use of materials.

-

Production Volume: If your company needs to package a large volume of products on a daily basis, you’ll need a high-speed automatic bagger capable of handling high throughput.

-

Cycle Time: Consider the cycle time, or how long it takes the machine to complete a full bagging process. Faster machines are great for high-volume production but may require a higher investment.

-

Customization: Some automatic bagger machines can be adjusted to fit different bag sizes, speeds, and product types, offering flexibility as your production needs evolve.

At Dostar Packing Equipment Co., Ltd., we offer customizable machines that allow you to optimize packaging speed based on your specific operational demands, from low to high-speed production lines.

3. Bag Type and Material Compatibility

Different products may require different types of bags, including plastic, paper, or even compostable materials. Choosing the right bag material and bag type is crucial to ensuring that the packaging protects your products while also aligning with your environmental goals.

-

Material Type: Some bagger machines are designed to work exclusively with specific types of materials like plastic or paper. If you want to offer eco-friendly packaging, look for a bagger machine that can handle biodegradable or recyclable materials.

-

Bag Style: Some packaging applications require stand-up pouches, pillow bags, or gusseted bags, each of which may require different mechanisms or adjustments on the bagging machine.

-

Bag Size and Weight: Different bagger machines accommodate different bag sizes. Make sure your chosen machine can handle the range of bag sizes and weights your products require.

At Dostar Packing Equipment Co., Ltd., we offer a range of automatic bagger machines that can accommodate a variety of bag types and materials, ensuring that you can meet your packaging goals while keeping production sustainable.

4. Automation Level: Semi-Automatic vs. Fully Automatic

Deciding between a semi-automatic and fully automatic bagger machine depends on your production capacity, budget, and level of automation you want to achieve.

-

Semi-Automatic Bagger Machines: These machines are ideal for small to medium-sized businesses or businesses with fluctuating packaging volumes. Semi-automatic systems often require manual intervention to load or seal the bags, but they can offer a more affordable solution while still increasing efficiency.

-

Fully Automatic Bagger Machines: For larger operations or businesses looking to automate their entire packaging line, a fully automatic bagger machine is a perfect choice. These machines require minimal human intervention and can handle the entire process from filling to sealing and even labeling, making them ideal for high-volume production environments.

At Dostar Packing Equipment Co., Ltd., we provide both semi-automatic and fully automatic packaging systems tailored to meet the unique needs of your business.

5. Durability and Maintenance

Durability is an essential consideration when investing in an automatic bagger machine. Since these machines are integral to your production process, choosing one that is built to last and requires minimal maintenance will save you time and money in the long run.

-

Machine Construction: Look for a machine made of high-quality, durable materials such as stainless steel, which is corrosion-resistant and easy to clean. This is especially important in industries like food packaging, where hygiene standards are strict.

-

Ease of Maintenance: Choose a machine that is easy to maintain and clean. Automatic baggers with self-diagnostic features or easy-to-access components make troubleshooting and repairs quicker and more efficient, reducing downtime.

At Dostar Packing Equipment Co., Ltd., we pride ourselves on providing machines that are not only highly durable but also easy to maintain, helping you keep your production line running smoothly with minimal interruptions.

6. Cost and Return on Investment (ROI)

While it’s tempting to choose the least expensive machine, investing in a high-quality automatic bagger machine can lead to greater long-term savings. High-quality machines often come with a higher upfront cost but can provide superior performance, longevity, and fewer maintenance needs, ultimately offering a better return on investment.

-

Initial Cost: The initial cost of an automatic bagger machine depends on its features, automation level, and speed. However, it’s important to weigh the cost against the potential improvements in productivity and reduced labor costs.

-

Operational Savings: A machine that operates more efficiently and requires fewer manual interventions can reduce labor costs and increase production capacity.

At Dostar Packing Equipment Co., Ltd., we offer cost-effective solutions that are designed to provide high ROI by improving packaging efficiency, reducing labor costs, and enhancing the overall reliability of your packaging line.

Conclusion

Choosing the right automatic bagger machine is a crucial decision that can have a significant impact on the efficiency and success of your packaging operations. By understanding the unique requirements of your product, evaluating factors like speed, bag material compatibility, and level of automation, you can make a well-informed decision that will optimize your production line.

At Dostar Packing Equipment Co., Ltd., we specialize in providing customized, high-quality packaging solutions that meet the needs of industries ranging from food and pharmaceuticals to consumer goods and beyond. Whether you need a semi-automatic system for small-scale operations or a fully automated packaging line for large production volumes, we have the expertise and technology to support your business.

If you're ready to take your packaging process to the next level, contact Dostar Packing Equipment Co., Ltd. today to learn more about our innovative automatic bagger machines and find the perfect solution for your business needs.