Understanding the Role of External Circulation Emulsifying Mixers in Modern Manufacturing

In modern manufacturing, achieving uniform and stable emulsions is essential across various industries, including pharmaceuticals, cosmetics, food processing, and chemical production. External circulation emulsifying mixers play a crucial role in ensuring high-quality emulsification, homogenization, and dispersion of ingredients. These advanced mixers improve product consistency, reduce processing times, and enhance efficiency, making them indispensable in today's production environments.

What is an External Circulation Emulsifying Mixer?

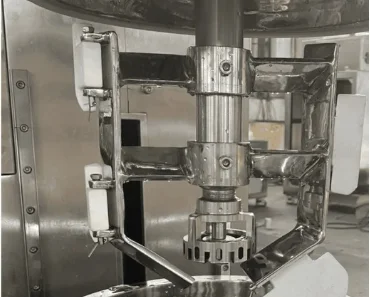

An external circulation emulsifying mixer is a specialized mixing system designed for continuous and efficient emulsification, homogenization, and dispersion of materials. Unlike traditional in-tank mixers, these systems recirculate the mixture through an external loop, ensuring better control over particle size reduction and uniformity.

Key Features of Orisun Recirculation Emulsifier Homogenizer

As a company specializing in mechanical design and manufacturing, Orisun has developed advanced emulsifying mixer solutions to meet the demanding requirements of industrial applications. The Orisun Recirculation Emulsifier Homogenizer is equipped with the following features:

Adjustable Loading Capacity: The system supports a wide range of volumes from 20L to 1000L, making it adaptable for small-scale to large-scale production.

High-Efficiency Vacuum System: The limit vacuum system operates above -0.095MPa, ensuring thorough deaeration and preventing unwanted oxidation.

Temperature Control with Water Jacket: The built-in water jacket system provides precise heating and cooling, allowing manufacturers to maintain optimal processing temperatures.

Automated Cleaning System: The CIP (Clean-In-Place) system enables automatic cleaning and washing, reducing downtime and ensuring compliance with hygiene standards.

Advantages of External Circulation Emulsifying Mixers

1. Superior Emulsification and Homogenization

The external circulation mechanism allows the mixture to pass through the emulsifying head multiple times, ensuring a more uniform particle size and stable emulsion.

2. Efficient Heat Exchange

With the integrated water jacket for heating and cooling, manufacturers can precisely control temperatures, preventing thermal degradation of sensitive materials.

3. Vacuum Deaeration for High-Quality Products

The limit vacuum system removes air bubbles, preventing oxidation and improving product stability, particularly in pharmaceutical and cosmetic formulations.

4. Continuous Processing for Increased Productivity

Unlike batch mixers, external circulation mixers facilitate continuous emulsification, reducing processing time and enhancing efficiency.

5. Automated Cleaning for Hygiene Compliance

The CIP (Clean-In-Place) system automates the cleaning process, minimizing manual labor and ensuring compliance with industry sanitation standards.

Applications of External Circulation Emulsifying Mixers

1. Pharmaceutical Industry

Used for the production of creams, ointments, and suspensions, ensuring uniform drug distribution and stability.

2. Cosmetics and Personal Care

Essential for manufacturing lotions, serums, and emulsions, achieving smooth textures and prolonged shelf life.

3. Food and Beverage Industry

Applied in the preparation of sauces, dairy products, and beverages, ensuring consistency and improving mouthfeel.

4. Chemical Industry

Utilized in paints, coatings, and lubricants, ensuring homogeneity and optimal dispersion of active ingredients.

Why Choose Orisun’s External Circulation Emulsifying Mixers?

With extensive experience in mechanical design and manufacturing, Orisun provides high-performance emulsifying solutions tailored to industrial needs. Their external circulation mixers are engineered for precision, efficiency, and reliability, making them the ideal choice for manufacturers seeking high-quality emulsification technology.

Key Reasons to Choose Orisun:

Innovative Design: Advanced emulsification technology ensuring superior mixing performance.

Customizable Capacities: Adaptable from 20L to 1000L to suit diverse production scales.

Reliable Quality: Rigorous testing and high-quality components ensure long-term performance.

Expert Support: Professional guidance and after-sales service to optimize your production processes.

Conclusion

External circulation emulsifying mixers have become a vital tool in modern manufacturing, enabling precise emulsification, improved efficiency, and enhanced product quality. Orisun’s advanced recirculation emulsifier homogenizers offer industry-leading features such as vacuum deaeration, temperature control, and automated cleaning, making them an excellent choice for manufacturers across multiple sectors.

For high-performance emulsification solutions, Orisun stands as a trusted partner, delivering cutting-edge mixing technology tailored to industrial demands.

Why Choose a Vacuum Emulsifying Homogenizer Mixer? Key Benefits and Solutions